From Blueprint to Partnership: Ecuador Client's Visiting Journey with Qingdao Jinggang

Qingdao Jinggang Steel Structure Co., Ltd., a pioneer in precision-engineered steel solutions, recently completed a factory tour with an Ecuadorian client, showcasing our end-to-end expertise from rapid quotation to onsite factory confirmation.

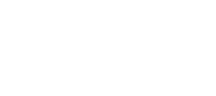

Stage 1: Rapid Technical Response & Transparent Quotation

March 13–14, 2025

Upon receiving the client’s inquiry and architectural drawings on March 13, our engineering team immediately initiated a timely analysis. By March 14, a detailed quotation was delivered, featuring:

· 1. Material Specifications: certified Chinese steel with 10+ years of supplier partnerships)

· 2. Cost Transparency: Breakdown of fabrication, surface treatment (galvanizing/painting), and logistics.

· 3. Timeline Guarantee: 30-45 days production time depending on the scale of the project.

Stage 2: Expanding Collaboration Through Expertise

March 19, 2025

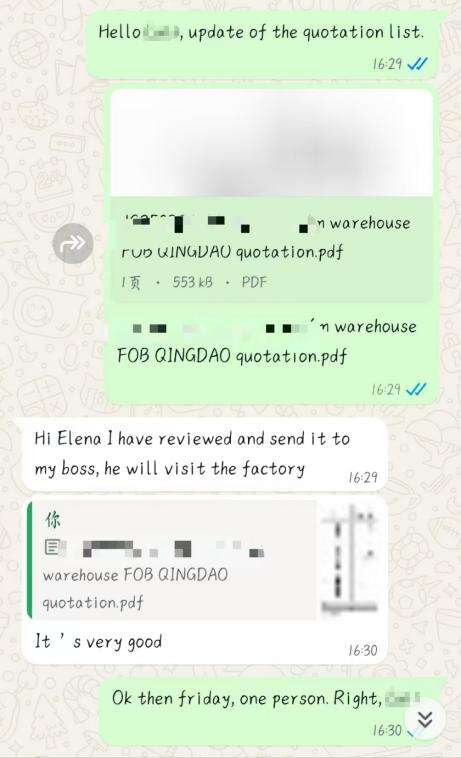

Impressed by our transparency and professional work, their team shared a second project with us via WhatsApp. After studing the drawing, we found it’s a complex of three buildings. Prioritizing accuracy, we first quoted one of the warehouses.

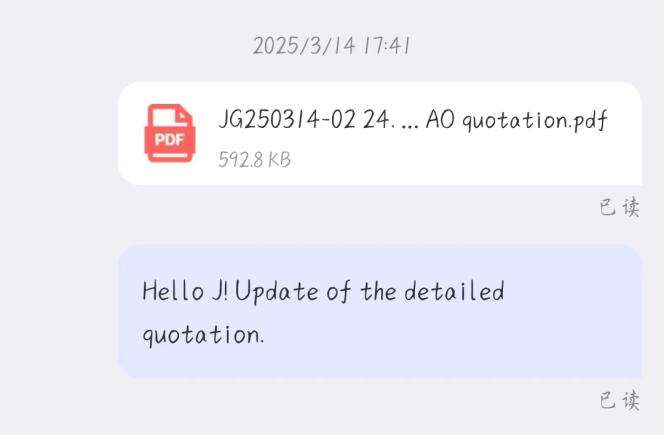

March 23, 2025

The customer expressed their desire to come for a factory inspection on March 24th at the last minute. We confirm travel information with the customer. However, due to temporary itinerary adjustments, it was ultimately decided to visit the factory on March 28th.

March 24th, 2025

We update our client with a quotation for the second project warehouse. The customer feedback is really very good.

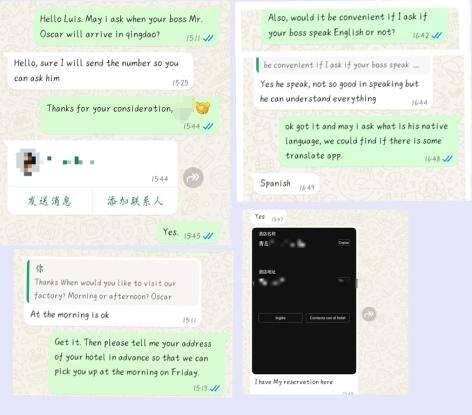

After confirming the visiting time, we gather information about the client's itinerary - including hotel details, expected visit time, and client’s English ability.

March 27, 2025

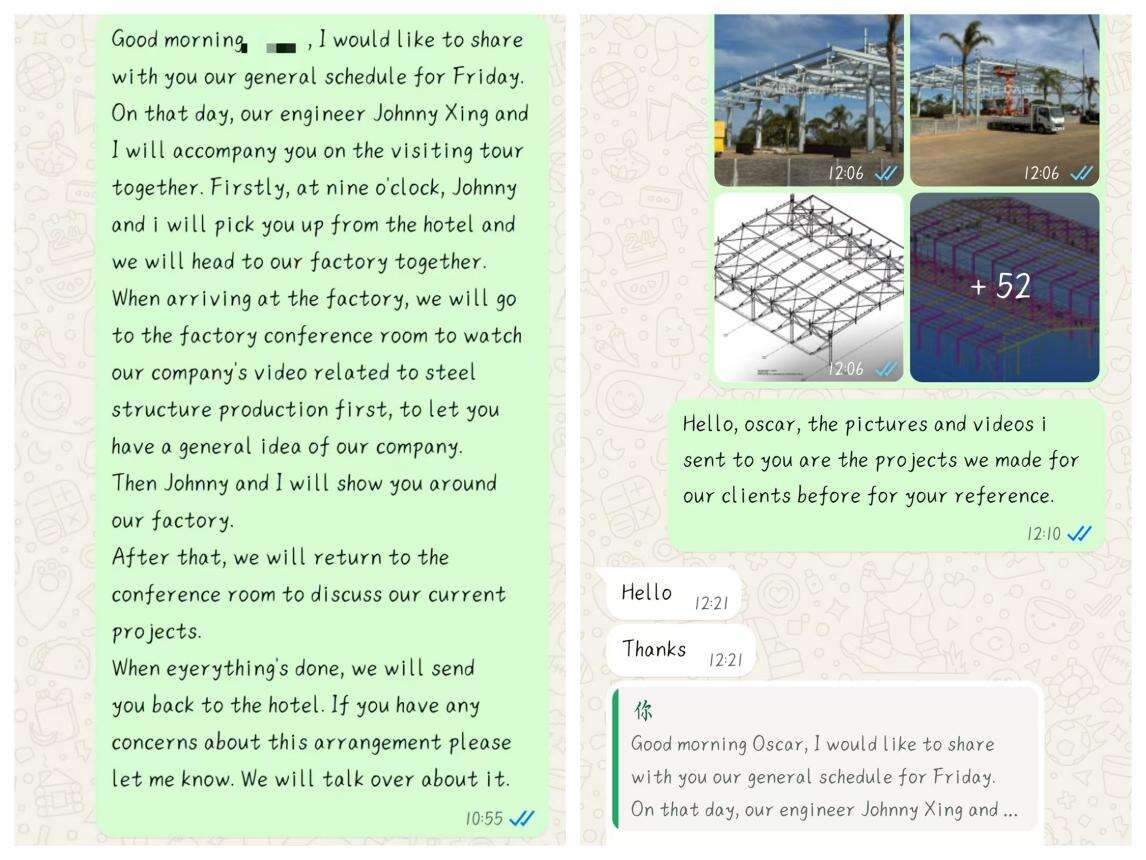

We finalized the next day’s activity schedule with the client and shared a set of images from our past projects and factory home-laboratory for their reference.

Stage 3: Seamless Factory Inspection Coordination

March 28, 2025 (Morning)

After picking up the client from his hotel, we departed for the factory.

During the journey to the factory, the client expressed interest in our South American project. We presented clients’ feedback pictures of completed projects, for example including:

v Colombia & Chile: Industrial warehouses with seismic-resistant designs.

v Suriname & Jamaica: Modular commercial complexes tailored to tropical climates.

Simultaneously, the client inquired about our corporate background and developing history. We emphasized:

v 20 years+ construction and 10 years+ production and export history: ensuring our rich experience in steel structure industry and also export issues solving.

v Material Sourcing: Steel sourced from Chinese big brand factory, backed by full sets marterial certificates.

v Cost Advantage: Over one decade of supplier partnerships with our cooperating materials factory enabling competitive pricing without compromising quality.

v Computer control and automated operation: ensuring the accuracy of each component and guaranteeing the stability of the building.

During this tour, our client team gained insights into:

v Quality Assurance: We highlighted our partnerships with certified Chinese steel suppliers, ensuring traceability and compliance with international standards (ISO, ASTM).

v Advanced Manufacturing: Production engineer Johnny Xing showcased cutting-edge CNC machinery, automated welding systems, and anti-corrosion treatment processes and so on.

v Proven Expertise: A presentation on our 10+ years of experience emphasized cost-efficiency through long-term supplier relationships and lean production techniques.

Factory visiting:

Photos with Elena:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

SQ

SQ

ET

ET

GL

GL

HU

HU

MS

MS

KA

KA

BN

BN

BS

BS

LA

LA

MI

MI

KK

KK

UZ

UZ

HAW

HAW